Nail Quality Importance for Pallet Performance

When it comes to pallet performance, most people think of the wood first—but the real unsung hero is often the nail. At Girard Wood Products, we’ve learned that fasteners are the backbone of a reliable pallet. A single nail can mean the difference between a pallet that holds strong under pressure and one that fails in the middle of a critical shipment.

That’s why we utilize premium-grade fasteners and state-of-the-art automation to ensure every pallet we produce exceeds industry standards for strength, consistency, and longevity.

The Power of a Stronger Nail

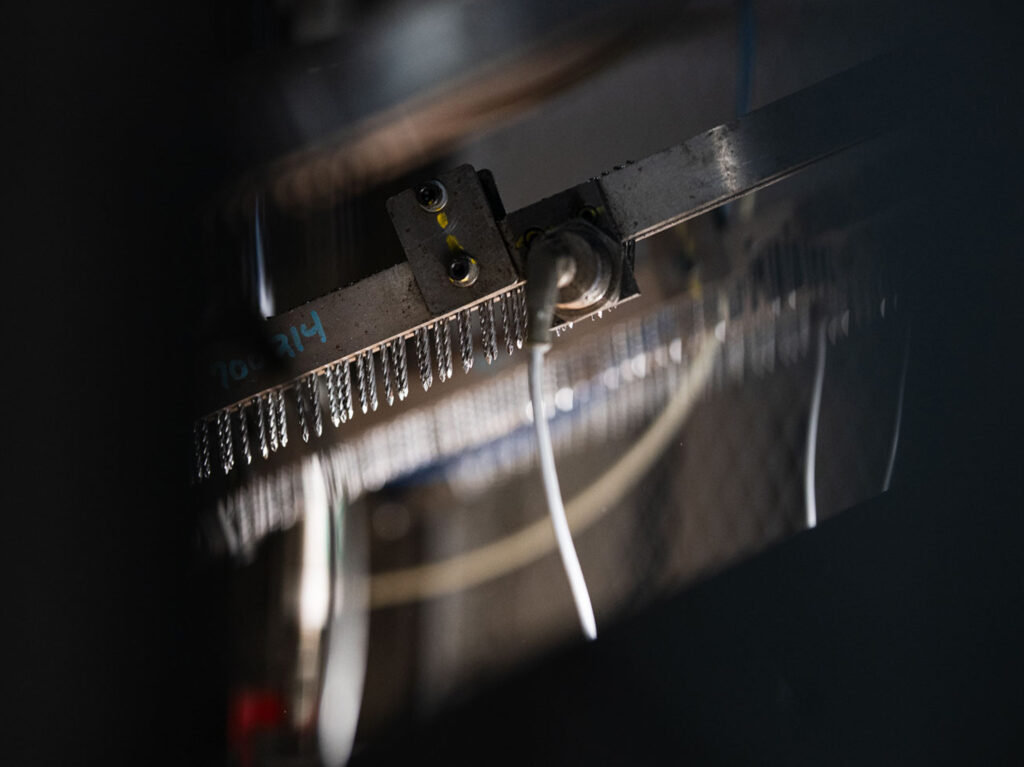

Not all nails are created equal. Girard’s top choice for fasteners are engineered for superior holding power and long-term structural integrity.

- Higher carbon content and thicker wire diameter give our nails the strength to resist bending, shearing, and loosening—even under heavy or shifting loads.

- Our Stiff Stock nails feature a five-flute screw shank pattern that twists into the wood, locking in securely and preventing the nail from backing out over time.

- The result? Pallets that stay tighter, stronger, and safer—reducing the risk of collapse or product damage in transit.

By reinforcing every joint with nails that are literally built to last, we help our customers avoid costly pallet failures, damaged goods, and supply chain interruptions.

Precision Manufacturing for Consistency and Speed

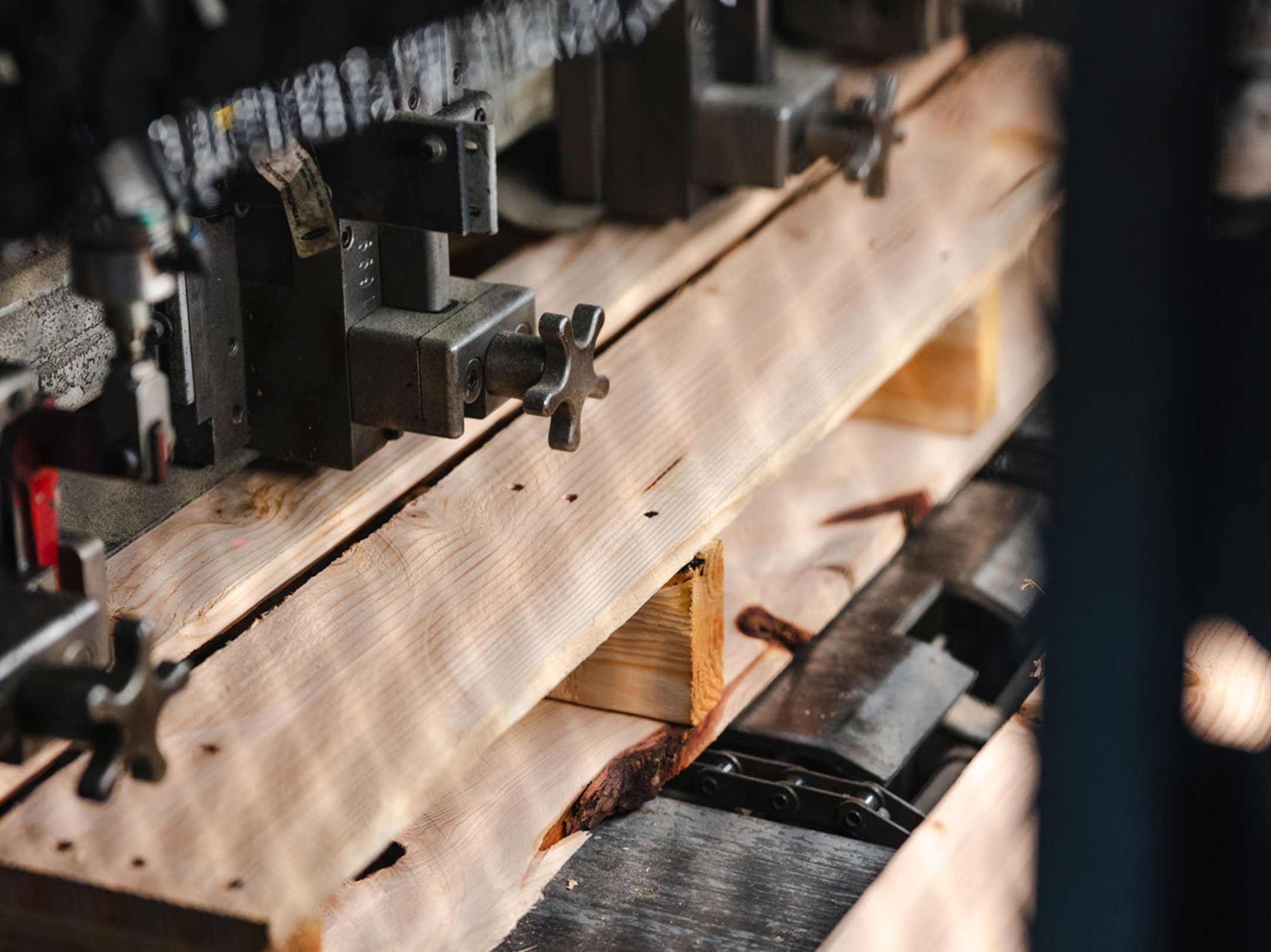

Girard Wood Products doesn’t just rely on better materials—we use cutting-edge automation to make sure every nail is driven with exact precision.

Our production lines feature automated material handling systems and high-speed nailing machines, each calibrated to deliver consistent fastening depth and alignment. This technology allows us to produce large orders efficiently without sacrificing quality.

From small-batch custom builds to full-scale production runs, our process ensures every pallet meets the same high-performance standard—down to the last nail.

Leading the Industry with Premium Fasteners

Our commitment to quality fasteners sets us apart from other pallet manufacturers. While many rely on nails with a .083 to .099 wire diameter, Girard uses C1042 premium-grade wire with a .113 wire diameter across our production lines.

- Greater diameter = greater holding power. The thicker wire dramatically increases joint strength and reduces the likelihood of fastener failure.

- Premium wire = premium performance. C1042 wire is specially chosen for its resistance to bending and breaking, even in high-stress environments.

- Longer service life. Stronger joints mean less flexing, fewer repairs, and longer-lasting pallets—saving customers money over time.

This level of precision and attention to detail ensures that every pallet leaving our facility is ready to perform in the toughest real-world conditions.

Built to Protect Your Product—and Your Reputation

A pallet’s job is simple: protect your goods. But when nails loosen, boards separate, or joints fail, the result isn’t just a broken pallet—it’s a potential claim, product loss, or damaged relationship with your customer.

By using quality fasteners and automated production systems, Girard Wood Products minimizes those risks. Every nail we drive reinforces our promise of durability, dependability, and quality.

The Girard Difference

From premium materials to cutting-edge automation, Girard Wood Products continues to lead the industry in pallet innovation. We don’t settle for standard—because our customers can’t afford to.

When you choose Girard, you’re choosing pallets designed to withstand the toughest loads, the longest hauls, and the highest expectations.

Choose Girard for Your New Wood Pallet Needs

Whether you need standard 48×40 pallets or a fully customized solution, our team has the technology, experience, and commitment to sustainability to support your operation for the long term.